Southern California, while not known for its Woodworking Market is one of the largest producers of finished wood products in the world. From Office Furniture to Commercial and Residential Furniture to Wood Blinds and Building Materials, Southern California boasts some of the largest and most state of the art

Woodworking plants in the world.

Whether the process involves sawing, cutting or sanding, Dust Collection Equipment has been a part of the Woodworking Industry since its beginning.

In 2002, Wood Dust was listed as a "known human carcinogen" by the National Toxicology Program. Because of this, most states, including California have developed more stringent requirements for the control of fugitive wood dust.

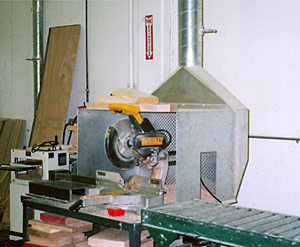

As with most dust producing processes, the preferred method of capturing wood dust is Source Capture; however, due to the difficulty of using Source Capture on a lot of woodworking machinery, free-hung, or ambient style Air Cleaning and Dust Collection Systems are prevalent as well.

While most modern-day woodworking equipment come equipped with some type of hood, guard or duct take-off, it is highly recommended that a Dust Collection expert be consulted, as the woodworking equipment

|

|

manufacturer doesn't always provide the proper capture device or recommended air volume to handle the job adequately. The types of Dust Collectors used in the Woodworking Industry run the gamut.

Small Shops may get by with relatively small Dust Collectors, such as Cabinet Collectors and small Cyclone/Afterfilter Systems, while larger production shops and Wood Mills will typically require large, Self-Cleaning Baghouse Systems. Common accessories used in this industry are Screw Conveyors, Rotary Valves, Explosion Relief Panels, Abrasion Resistant Inlets and Fire Supression Systems. Donaldson/Torit offers all of these options as standard accessories to their product lines. As with any Dust Collection System, the Industrial Ventilation Manual should be consulted for guidance on proper duct and hood design.

|