Manufacturers of parts and components for the Electronics, High Tech and Telecommunications Industries. Time Savers or Belt Sanders are used to put a fine finish on metal parts and components. This fine dust was both a personnel safety hazard as well as a problem for expensive electronic equipment.

Location: Camarillo, CA

Installation Date: 2000

Type of Polutant: Fine Steel and Aluminum Dust

Airflow: (2) 2,000 cfm units

Capture Method:

Source Capture. The Belt Sanders came equipped with a duct connection already on it. By ducting directly to the machine, the dust created by the sanding process is pulled up and away from the opening at the bottom of the machine.

|

|

Filtration System:

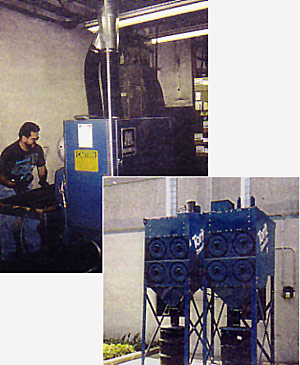

Two Self-Cleaning (4) Cartridge Dust Collection Systems are installed. The Steel and Aluminum dust is separated into two units as required by Local Fire Code and The National Fire Protection Agency. The units are also equipped with explosion relief panels.

|